Commissioning of the Process (Glycol) Chillers @ Confidential Client Dublin was carried out in early 2018 , at that time it was necessary to place a heat load on the system to prevent the chillers going into fault and maintain reliability . This heat load was provided via the Tempered Glycol System which in turn added additional cooling load to the Glycol Chillers.

An energy analysis study was undertaken to identify the impact of this change looking at the chiller electrical load , chiller supply & return temperature data which determined that there was a significant cost associated with adding tempered glycol heat load .

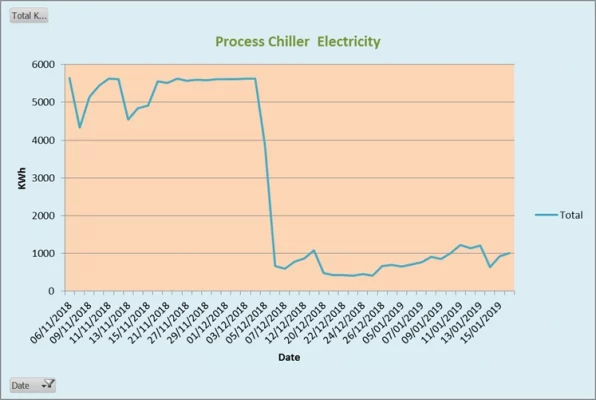

A Building Management System (BMS) control strategy change was initiated that enabled a more optimised control of the chiller duty and eliminate the need for the tempered glycol addition . This work was completed on 5th December and the additional Tempered Glycol heat load was removed.

Savings

Electricity :

Prior to change the Process Chiller daily electricity demand was 5,500 KWh , after the BMS change was made on 5th December 2018 demand dropped to 900 KWh.

Total Energy Reduction = 4,600 KWh/Day or 138,000 KWh/Month Electrical Cost Saving = €15,870 Month

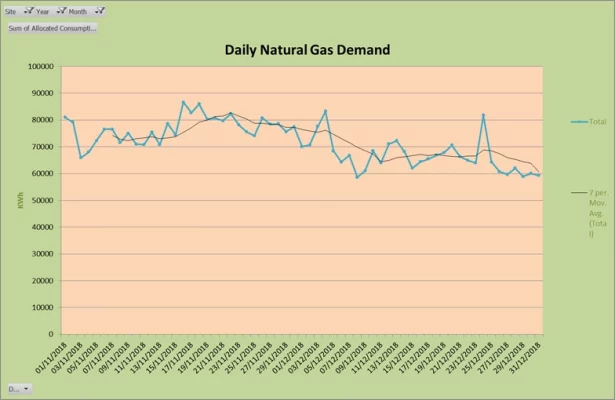

Natural Gas :

As a result of the change there was a reduction in the heat load to the Tempered Glycol system as the load to the Process Chillers had been removed . The total thermal load reduction was 10,700 KWh/day

Gas Energy Reduction = 10,700 KWh/Day or 321,000 KWh/Month Total Gas Saving (@€0.036 kWh) = €10,785 Month